- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

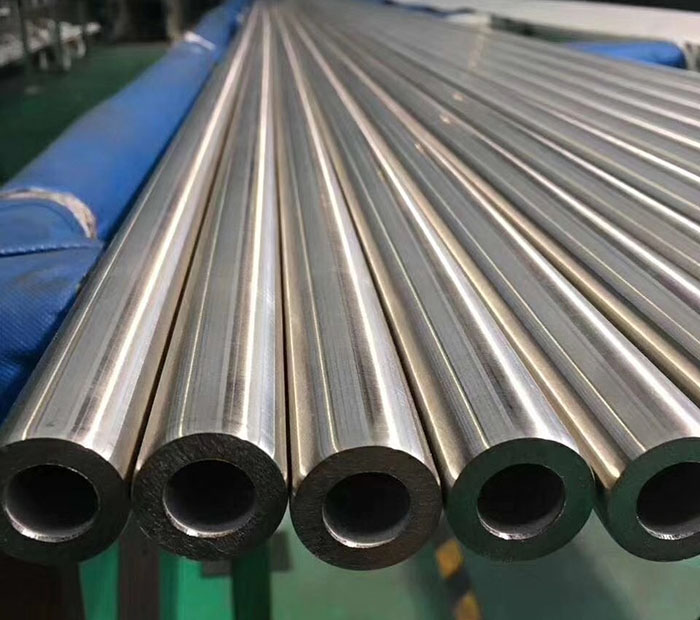

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

ASTM A321 TP321 seamless welded pipe and tube

-

Type: Seamless, Welded

OD: 1/2"-48"

Thickness: SCH5-SCHXXS

Length: 0-12M, Customized

Process: Hot/Cold Rolled,Hot work,Cold drawn

ASTM A312 Stainless Steel 321 Pipes Manufacturers, 321 Seamless Stainless Tubing, 321 Bright Anneal Seamless Pipe Suppliers, Seamless Stainless Pipe, ASTM A321 Stainless Welded Steel Pipe Manufacturers, ASTM A213 / A249 / A269 Stainless Steel 321 Tubes Suppliers, 321 Stainless Steel Pipe Manufacturers, Astm A321 Stainless Welded Steel Pipe In China.

ASTM A312 Stainless Steel 321 Pipes Manufacturers:

Stainless steel is one of the most used materials in the world for various purposes and the 304 grade of steel is the most common of them. ASTM A312 Stainless Steel 321 Pipes are a chromium nickel austenitic stainless steel pipe that has mild corrosion resistance, good strength and good wear and tear properties. There are times when the 321 Seamless Stainless Tubing properties have to be better without going to another grade of steel. At requirements like this, the material is altered by altering the chemical composition.

In case of the ASTM A312 Stainless Steel 321 Pipes, the carbon content could be altered to bring less chromium carbide precipitation while welding or the carbon content could be increased to bring more toughness and wear and tear resistance. The high carbon content ASTM A321 Stainless Welded Steel Pipe material is called the 304H, whereas the low carbon variation is called the 304L. So, the H in the Stainless Steel 321 Tube means it has high carbon content. The same applies for many other grades of stainless steels as well. The high carbon version also does not have a 0.1% nitrogen limit in their composition opposed to the lower carbon versions.

ASTM A321 TP321 Seamless Welded Pipe And Tube

Grades 321 and 347 are the basic austenitic 18/8 steel (Grade 304) stabilized by Titanium (321) or Niobium (347) additions. These grades are used because they are not sensitive to intergranular corrosion after heating within the carbide precipitation range of 425-850 °C. The 321 stainless steel pipe is the grade of choice for applications in the temperature range of up to about 900 °C, combining high strength, resistance to scaling and phase stability with resistance to subsequent aqueous corrosion.

Due to the stability of 321 stainless steel pipe, the material is known for its resistance to intergranular corrosion. This makes it suitable for applications at intermittent operating temperatures. SS 321 Seamless Pipe has a minimum tensile strength of 515 Mpa. Adding titanium to the alloy increases its strength. Alloy 321 is commonly used in engineering and chemical equipment. It has a maximum hardness of Rockwell 95 HRB.

In addition to its machinability, SS 321 steel is also resistant to atmospheric corrosion, inorganic chemicals and chlorides. Stainless steel 321 is suitable for applications involving high temperatures. SS 321 pipe is preferred in the high temperature range due to better strength and formability compared to SS 304L pipe. Additionally, it can be welded in place using standard shop fabrication procedures. Typically, it is used for functions between 800 and 1650 degrees Celsius.

Typical compositional ranges for grade 321 stainless sheets of steel are given in table 1.

Table 1. Composition ranges for 321-grade stainless steel

Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Other | |

321 | min. | - | 2.00 | 0.75 | 0.045 | 0.030 | 17.0 | - | 9.0 | 0.10 | Ti=5(C+N) |

321H | min. | 0.04 | 2.00 | 0.75 | 0.045 | 0.030 | 17.0 | - | 9.0 | - | Ti=4(C+N) |

347 | min. | 0.08 | 2.00 | 0.75 | 0.045 | 0.030 | 17.0 | - | 9.0 | - | Nb=10(C+N) |

Mechanical Properties

Typical mechanical properties for grade 321 stainless sheets of steel are given in table 2.

Table 2. Mechanical properties of 321-grade stainless steel

Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50 mm) min | Hardness | |

Rockwell B (HR B) max | Brinell (HB) max | ||||

321 | 515 | 205 | 40 | 95 | 217 |

321H | 515 | 205 | 40 | 95 | 217 |

347 | 515 | 205 | 40 | 92 | 201 |

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone