- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

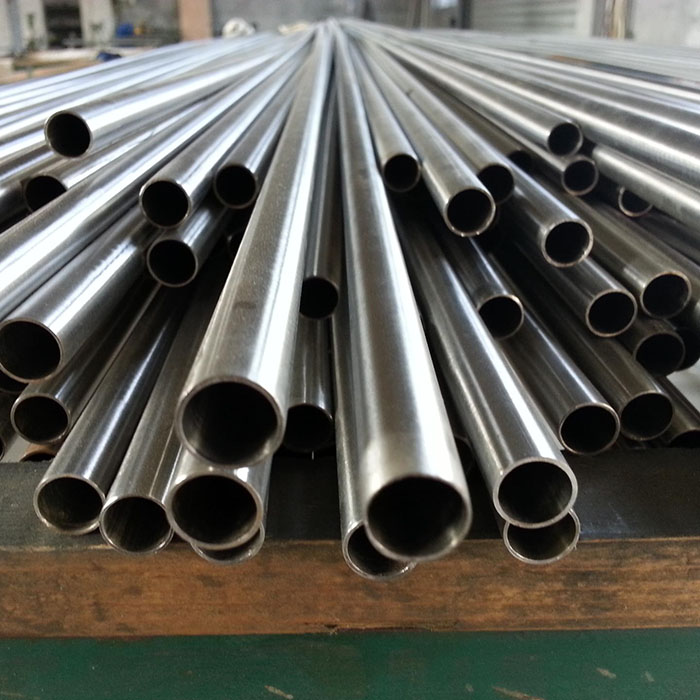

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

ASTM A790 S31803 Steel Pipe

-

Type: Seamless, Welded

OD: 1/2"-48"

Thickness: SCH5-SCHXXS

Length: 0-12M, Customized

Process: Hot/Cold Rolled,Hot work,Cold drawn

ASTM A790 is the standard specification for seamless and welded duplex stainless steel pipe. The ASTM A790 UNS S31803 steel pipe has gained widespread popularity due to its excellent properties, including high strength, good fatigue resistance, and corrosion resistance.

HT PIPE Supply ASTM A790 Duplex Stainless Steel Pipes in Grades UNS S32205, UNS S31803, UNS S32750, UNS S32760, SAF 2205, SAF 2507 etc, UNS S31803 Pipe, duplex 2205 seamless pipe, S31803 seamless pipe, 2205 stainless steel pipe manufacturer, duplex 2205 welded pipe suppliers, duplex 1.4462 pipe, duplex 2205 tube, duplex 2205 seamless tube exporter in China.

The manufacturing process for the S31803 steel pipes involves two distinct methods, including the seamless method and the welded method. The seamless method involves heating and pressing the billet into a hydraulic punch. This process is repeated multiple times until the desired thickness and size are achieved. On the other hand, the welded method involves heating two separate pieces of steel to melting point and welding them together.

The Standard Specification For Duplex Steel ASTM A790 S31803 Steel Pipe

| Standards | ASTM / ASME A790, A928, A789 / SA790, SA928, SA789 |

| Outer Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB |

| Thickness | 0.3mm – 50 mm |

| Type | Seamless / ERW / EFW / Welded / Fabricated / LSAW Pipes |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Seamless Pipes & Tubes Size | 1 / 8″ NB – 24″ NB |

| ERW Pipes & Tubes Size | 1 / 8″ NB – 36″ NB |

| EFW Pipes & Tubes Size | 6″ NB – 100″ NB |

| Length | Single Random, Double Random & Required Length |

| Form | Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

| End | Plain End, Beveled End, Treaded |

ASTM A790 material UNS S31803 Chemical Composition

| Chemical Element | % Present |

| Carbon (C) | 0.0 - 0.03 |

| Chromium (Cr) | 21.00 - 23.00 |

| Manganese (Mn) | 2.00 max |

| Silicon (Si) | 1.00 max |

| Phosphorous (P) | 0.0 - 0.03 |

| Sulphur (S) | 0.0 - 0.02 |

| Nickel (Ni) | 4.50 - 6.50 |

| Nitrogen (N) | 0.08 - 0.20 |

| Molybdenum (Mo) | 2.50 - 3.50 |

| Iron (Fe) | Balance |

ASTM A790 S31803 duplex steel pipe Mechanical Composition

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation(% in 50mm) min | Hardness | |

| Rockwell C (HR C) | Brinell (HB) | ||||

| UNS S31803 / 2205 | 621 | 448 | 25 | 31 max | 293 max |

S31803 duplex stainless steel pipe Physical Properties

| Grade | Density (kg/m3) | Elastic Modulus(GPa) | Mean Co-eff of Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat | Electrical Resistivity | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | 0-100°C( J/kg.K) | (nΩ.m) | |||

| UNS S31803 / 2205 | 782 | 190 | 13.7 | 14.2 | - | 19 | - | 418 | 850 |

- Corrosion resistance: The duplex stainless steel pipe is highly resistant to corrosion from chemical substances and seawater.

- High strength: The S31803 steel pipe has a high tensile and yield strength that makes it ideal for industrial applications.

- Fatigue resistance: The material's duplex phase structure makes it resistant to fatigue and creep.

- High thermal conductivity: The S31803 steel pipe has excellent thermal conductivity properties.

- Weldability: The S31803 steel pipe has good weldability and can be welded without requiring pre-heating.

ASTM A790 UNS S31803 Pipe Applications:

- Oil and gas exploration and production

- Chemical processing

- Heat exchangers

- Desalination plants

- Marine applications

- Pulp and paper industry

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone