- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

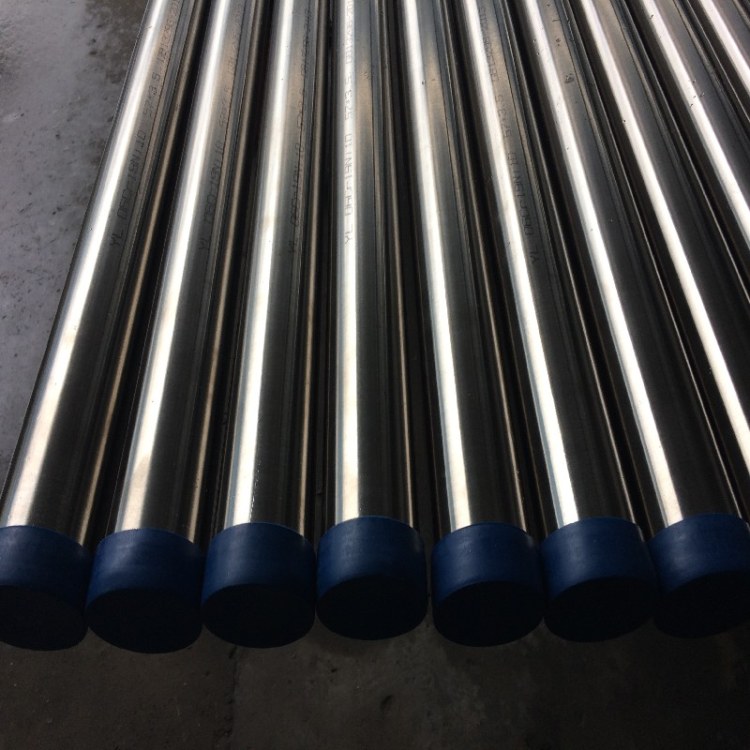

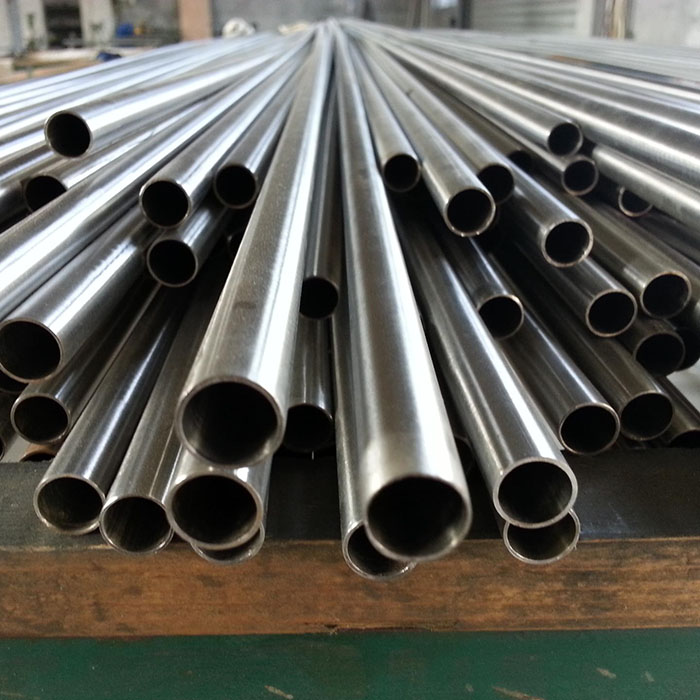

904L Pipe

-

Type: Seamless, Welded

OD: 1/2"-48"

Thickness: SCH5-SCHXXS

Standard: ASTM A312, ASTM A213, ASTM A269, ASTM A249,ASTM B677

Process: Hot/Cold Rolled,Hot work,Cold drawn

HT PIEP is a leading Manufacturer, Exporter, Supplier and Stockist of SS 904L Plates, Pipes and Tubes, WNR 1.4539 Welded Pipes, WNR 1.4539 EFW Pipes, UNS N08904 Pipes, SS 904L EFW Pipes, UNS N08904 EFW Pipes, 904l stainless steel Pipes, SS 904L WELDED Pipes, UNS N80904 WELDED Pipes, WNR 1.4539 WELDED Pipes, Alloy 904l Pipes, 904l stainless steel tube, 904l stainless steel suppliers, 904l stainless steel seamless pipe.

We are one of the leading suppliers, manufacturer , exporter and stockist of SS 904L Pipes, UNS N08904 Pipes, ASTM A312 904L Pipes, ASTM A213 904L seamless tubes according to the standard ASTM A312, ASTM A213, ASTM A269, ASTM B677, ASTM A249.

Stainless steel 904L Pipe Specification

| Pipe Specifications | ASTM A312 / ASME SA 312, ASTM A213 / ASME SA 213, ASTM A269 / ASME SA 269, ASTM A249 / ASME SA 249, ASTM b677 / ASME Sb 677 |

| Pipe Standard | DIN, JIS, ASTM, EN, GB, AISI, ASME |

| Pipe Thickness | 0.3mm - 50 mm |

| Welded Pipe size | 5.0 mm - 1219.2 mm |

| Seamless Pipe Outer Diameter | 6.00 mm OD up to 250 mm OD, Sizes up to 12” NB |

| Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Seamless Tube Size | 3.35 mm OD To 101.6 mm OD, 15 NB to 150 NB IN |

| Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Pipe & Tube Type | Seamless / ERW/ EFW / Welded / Fabricated Pipe |

| Pipe & Tube End | Plain End, Beveled End, Treaded Pipe. |

1.Applications

Alloy 904 & 904L (N08904) stainless steel pipe, fittings and flanges are used in the chemical industry to process corrosive chemicals such as: Acetic acid, Acetylene, Acrylates, Acrylonitrile, Aluminum sulfate, Ammonium phosphate, Ammonium sulfate, Battery acid, Benzene, Butyl acetate, Caprolactum, Cellophane, Citric acid, Nitrophosphate, Oxalic acid, Superphosphate, Tall oil, Tartaric acid, Uranium oxide and Zinc sulfate.

2.Properties

Alloy 904 (N08904) stainless steel is a high alloy austenitic product intended for use under severely corrosive conditions. It offers good resistance to:

Pitting and crevice corrosion

Intergranular corrosion

Stress corrosion cracking

General corrosion

Grade 904L stainless steel is a non-stabilized austenitic stainless steel with low carbon content. This high alloy stainless steel has added copper to improve its resistance to strong reducing acids, such as sulphuric acid. The steel is also resistant to stress corrosion cracking and crevice corrosion. Grade 904L stainless steel is non-magnetic, and offers excellent formability, toughness and weldability. Grade 904L contains high amounts of expensive ingredients, such as molybdenum and nickel. Today, most of the applications that employ grade 904L are replaced by low-cost duplex stainless steel 2205.

Grade 904L stainless steels have excellent resistance to warm seawater and chloride attack. The high resistance of grade 904L against stress corrosion cracking is due to the presence of high amounts of nickel in its composition. Moreover, the addition of copper to these grades develops resistance to sulphuric acid and other reducing agents in both aggressive and mild conditions.

The corrosion resistance of grade 904L is intermediate between super austenitic grades, with 6% molybdenum content, and standard 316L austenitic grades. Grade 904L is less resistant to nitric acid than grades 304L and 310L, which are free of molybdenum. This steel grade needs to be solution treated following cold working, to achieve maximum stress corrosion cracking resistance under critical environments.

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone