- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

N04400 Monel 400 Plate Sheet Strp Coil

-

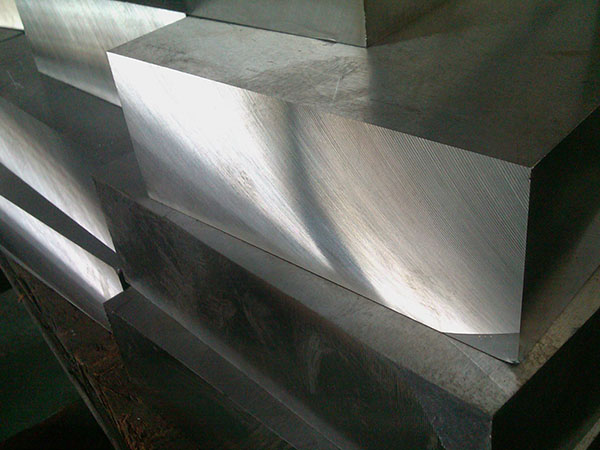

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

Nickel Alloy 400 Sheet manufacturer, Check UNS N04400 Strip, Monel 400 Coil, Alloy UNS N04400 Shim Sheets, ASTM B127 400 Monel Polished Cold Drawn Plates, Nickel Alloy 400 Sheet, UNS N04400 Strip

The length of the Nickel Alloy 400 Plate ranges from 200mm to 6000mm and the width ranges from 1000mm to 2000mm and the thickness varies from 0.3mm to 20mm. The Monel 400 Coil is also hard with NACE MR 175 hardness score. The UNS N04400 Strip can come in different finishes such as the hot rolled or cold rolled finishes. The Alloy UNS N04400 Shim Sheet supports, cutting, forming, grinding and polishing operations. The chemical composition of UNS N04400 Strip includes 63% nickel, iron, 28% copper, carbon, manganese, silicon and sulfur.

The UNS N04400 Strip is a narrow form of the plate. Monel 400 Plate is used in lining applications and to fill in gaps in larger plate structures. The Monel 400 Coils are also used to produce pipes and tubes of the same grade of material. The material has higher density than the 304 grade steels. The density is 8.8 grams per centimeter cube. As one of the leading Monel 400 Coil Suppliers, HT PIPE manufactures and supplies the Alloy 400 Plates for various high temperature applications. The high operating temperature of the material comes from the high melting point of 1350 degrees Celsius. Nickel Alloy 400 Sheet also has 240MPa minimum yield strength and 550MPa minimum tensile strength. Please contact us for more information on the ASTM B127 400 Monel Shim Sheets, plates, strips, coils and their prices.

In what forms is Monel 400 Available?

• Sheet

• Plate

• Bar

• Pipe & Tube (welded & seamless)

• Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints, long

welding necks, socket welds, elbows, tees, stub-ends, returns, caps,

crosses, reducers, and pipe nipples)

• Wire

What are the characteristics of Monel 400?

• Resistant to seawater and steam at high temperatures

• Excellent resistance to rapidly flowing brackish water or seawater

• Excellent resistance to stress corrosion cracking in most freshwaters

• Particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated

• Offers some resistance to hydrochloric and sulfuric acids at modest

temperatures and concentrations, but is seldom the material of choice

for these acids

• Excellent resistance to neutral and alkaline salt

• Resistance to chloride induced stress corrosion cracking

• Good mechanical properties from sub-zero temperatures up to 1020° F

• High resistance to alkalis

Chemical Composition, %

C | Mn | S | Si | Ni | Cu | Fe |

.30 max | 2.00 max | .024 max | .50 max | 63.0 min | 28.0-34.0 | 2.50 max |

Corrosion Resistant Monel 400

Alloy 400 is virtually immune to chloride ion stress corrosion cracking in typical environments. Generally, its corrosion resistance is very good in reducing environments, but poor in oxidizing conditions. It is not useful in oxidizing acids, such as nitric acid and nitrous. Nevertheless, it is resistant to most alkalis, salts, waters, food products, organic substances and atmospheric conditions at normal and elevated temperatures.

This nickel alloy is attacked in sulfur-bearing gases above

approximately 700° F and molten sulfur attacks the alloy at temperatures

over approximately 500° F. Monel 400 offers about the same corrosion

resistance as nickel but with higher maximum working pressures and

temperatures and at a lower cost due to its superior ability to be

machined.

In what applications is Monel 400 used?

• Marine engineering

• Chemical and hydrocarbon processing equipment

• Gasoline and freshwater tanks

• Crude petroleum stills

• De-aerating heaters

• Boiler feed water heaters and other heat exchangers

• Valves, pumps, shafts, fittings, and fasteners

• Industrial heat exchangers

• Chlorinated solvents

• Crude oil distillation towers

Fabrication with Monel 400

Alloy 400 can easily be welded by gas-tungsten arc, gas metal arc or

shielded metal arc processes using appropriate filler metals. There is

no need for post weld heat treatment, however, thorough cleaning after

welding is critical for optimum corrosion resistance, otherwise there is

the risk of contamination and embrittlement.

Finished fabrications can be produced to a wide range of mechanical

properties when proper control of the amount of hot or cold working and

the selection of appropriate thermal treatments is done.

Like most other nickel alloys, Monel 400 is typically tough to machine

and will work harden. However, excellent results can e obtained if you

make the correct choices for tooling and machining.

ASTM Specifications

Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Forging | Fitting | Wire |

B165 | B725 | B163 | B127 | B164 | B564 | B366 |

Mechanical Properties

Typical room temperature Tensile Properties of Annealed Material

Product Form | Condition | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) | Hardness (HRB) |

Rod & Bar | Annealed | 75-90 | 25-50 | 60-35 | 60-80 |

Rod & Bar | Cold-Drawn Stress Relieved | 84-120 | 55-100 | 40-22 | 85-20 HRC |

Plate | Annealed | 70-85 | 28-50 | 50-35 | 60-76 |

Sheet | Annealed | 70-85 | 30-45 | 45-35 | 65-80 |

Tube & Pipe Seamless | Annealed | 70-85 | 25-45 | 50-35 | 75 max * |

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone