- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

ASTM B444 UNS N06625 Inconel 625 Pipe Tube

-

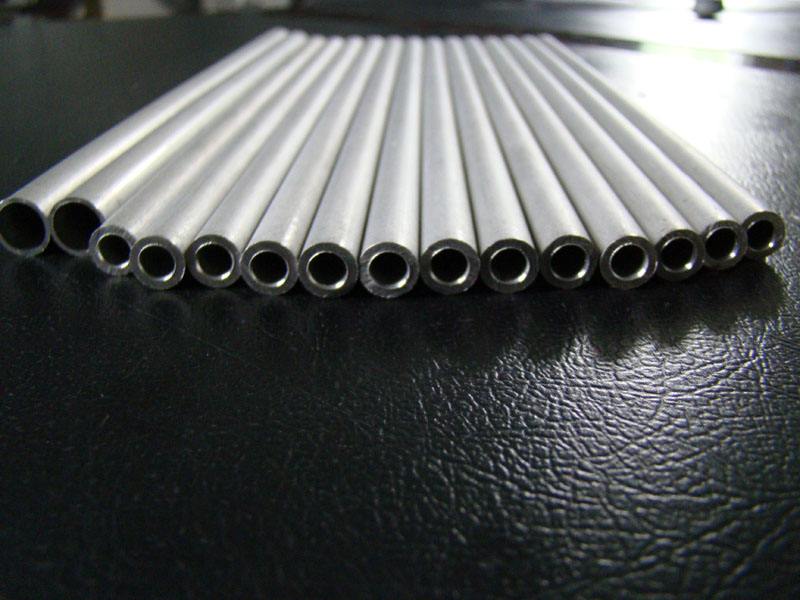

Type: Seamless, Welded

OD: 1/2"-48"

Thickness: SCH5-SCHXXS

Length: 0-12M, Customized

Process: Hot/Cold Rolled,Hot work,Cold drawn

ASTM B444 UNS N06625 inconel 625 pipe Product Description:

Inconel Alloy 625 (UNS N06625.W.Nr. 2.4856) is an austenitic nickel-based superalloy known for its high strength at elevated temperatures, excellent machinability, and excellent oxidation resistance under a wide range of corrosive conditions and corrosion resistance.

ASTM B444 UNS N06625 Inconel 625 has high strength and toughness in the low temperature range to 2000°F (1093°C) due to the solid solution effect of refractory metals, niobium and molybdenum in a nickel-chromium matrix. Nickel alloy Inconel 625 has excellent fatigue strength and stress corrosion cracking resistance to chloride ions. Additionally, the corrosion resistance of Inconel 625, especially over a wide temperature and pressure range, makes Inconel Alloy 625 Tubing ideal for the chemical processing industry for thin-wall vessels or tubing, heat exchangers, transfer piping, and valves.

ASTM B444 UNS N06625 Steel Pipe Type:

ERW pipe, EFW pipe, SSAW pipe, LSAW pipe, SAW pipe

Standard: ANSI B36.10M-2004, ASME B36.19M-2004

Size:(0.4 inch-31.97inch)SMLS/ERW (8.62inch-95.98inch)SSAW

Length:Double random length(11.5m~12m)

Single random length(5.8m~6m) According to customers' requirements.

Nickel alloy steel Alloy 625/Inconel 625/NO6625/NS336/2.4856

ASTM B444 UNS N06625 Steel Pipes are furnished in two grades of different heat-treated conditions:

Grade 1 (annealed)—Material is normally employed in service temperatures up to 1100°F (593°C).

Grade 2 (solution annealed)—Material is normally employed in service temperatures above 1100°F (593°C) when resistance to creep and rupture is required.

ASTM B444 UNS N06625 Steel Pipes Properties

| Alloy N06625 | Tensile Strength, min, ksi (MPa) | Yield Strength (0.2 % offset), min, ksi (MPa) | Elongation in 2 in. or 50.8 mm (or 4D), min, % |

| Grade 1 (annealed) | 120 (827) | 60 (414) | 30 |

| Grade 2 (solution annealed) | 100 (690) | 40 (276) | 30 |

Note:

Annealed at 1600°F (871°C) minimum.

Solution annealed at 2000°F (1093°C) minimum, with or without subsequent stabilization anneal at 1800°F (982°C) minimum to increase resistance to sensitization.

ASTM B444 UNS N06625 Steel Pipe Application

chemical processing

aerospace industry

marine engineering

nuclear power plants

oil and gas industry

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone