- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

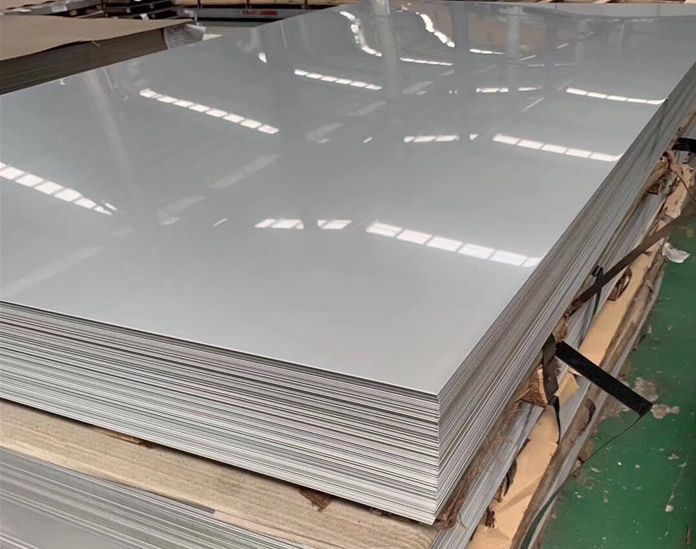

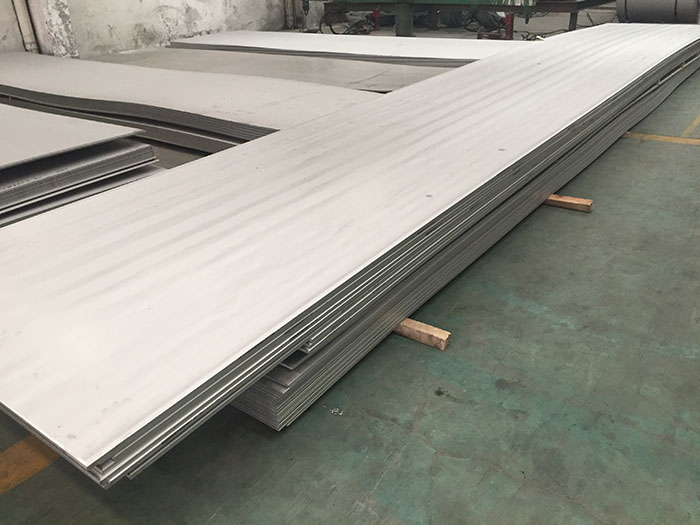

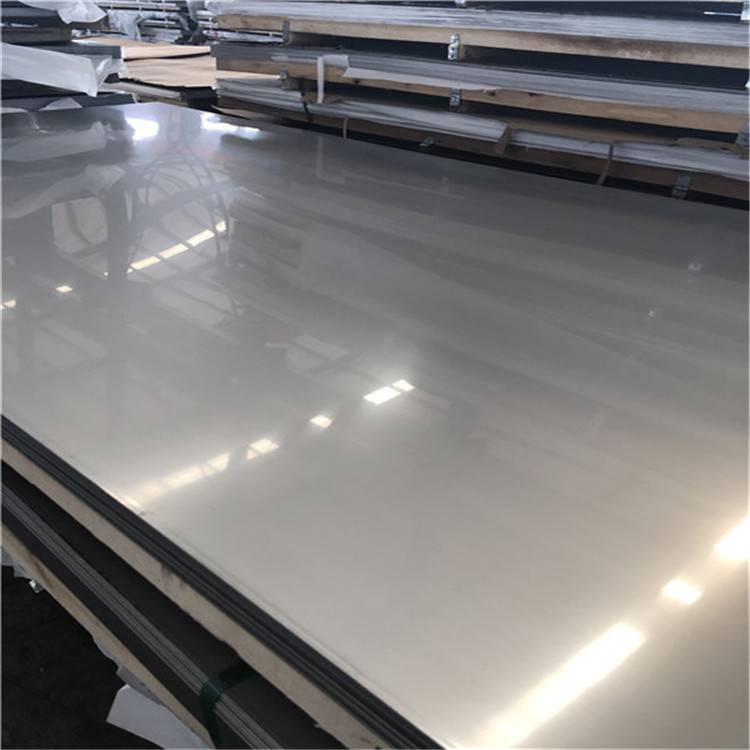

Hot Rolled Incoloy 825 Aloy 825 UNS N08825 W.Nr.2.4858 NS142 NA16 Plate Sheet Coil Strip Manufacturer In China

-

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

Hot Rolled Incoloy 825 Aloy 825 UNS N08825 W.Nr.2.4858 NS142 NA16 Plate Sheet Coil Strip Manufacturer in China

Incoloy 825 Sheet was brought to the market in 1952, building upon Incoloy 800 in order to better resist sulphuric acid. Copper additions are well-known to improve resistance to reducing environments, such as sulphuric acid. This property of Incoloy 825 Sheet is also exploited in Ferralium 255 (containing 2% copper additions) and the much more highly alloyed Alloy 20 (3-4% copper) to great effect. Although the nickel content is lower than the likes of Inconel 625 and Inconel 718, UNS N08825 plate is still sufficient to impart resistance to stress corrosion cracking (SCC) in chloride-containing environments. The increased chromium content of W.Nr.2.4858 plate ensures good resistance to oxidising environments such as nitric acid, whilst the molybdenum additions are well-known to improve pitting corrosion resistance.

The mechanical properties of Incoloy 825 Sheet is relatively constant from very low temperatures (considered cryogenic i.e. -150degC) up to 540degC (100degF). Above this temperature there is the possibility of undesirable microstructural phase changes that significantly reduce impact toughness and elongation.

Chemical Composition of Incoloy Alloy 825 Sheet & Plate

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy 825 | 0.05 max | 1 max | 0.5 max | 0.03 max | 1.50 – 3 | 22.00 min | 38 – 46 | 19.50 – 23.50 | 0.02 max | 0.06 – 1.20 |

Physical Properties

| Density (Kg.m-1) | 81.4 |

| Magnetic Permeability (20°C) | 1.005 |

| Curie Temperature (°C) | -196 |

| Young’s Modulus (N/mm2) | 196 |

| Specific Heat, 20°C (J/(g.K)) | 440 |

| Specific Electrical Resistance, 20°C (Ω-m) | 0.00113 |

| Thermal conductivity, 20°C (W/(m.K)) | 10.8 |

| Mean coefficient of thermal expansion, 20-100°C (/K) | 14.1 x 10-6 |

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone