- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

Inconel 600 Hot Rolled Sheet

-

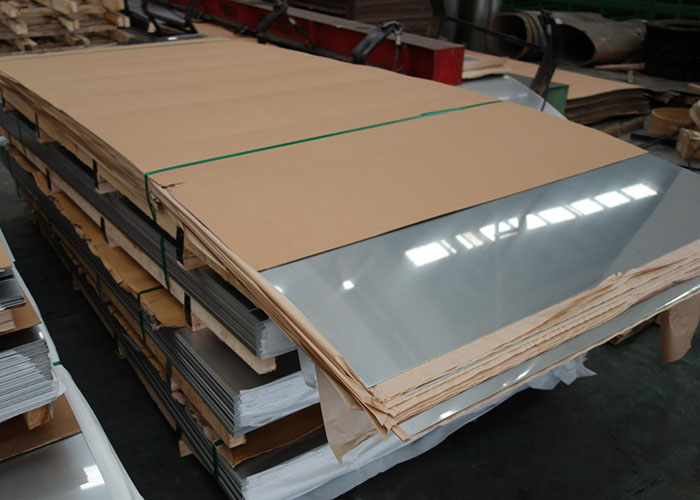

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

ASTM B168 AMS 5540 Inconel 600 UNS N06600 Steel Plate Sheet Coil

Inconel 600 is a unique nickel-chromium alloy that is known for its oxidation resistance at higher temperatures. Inconel 600 Hot Rolled Sheet is highly versatile and can be used in everything from cryogenics to applications that present elevated temperatures up to 2000°F (1093°C). Inconel 600 Hot Rolled Sheet is used in the aerospace industry during applications where intensely high temperatures can be present, such as in jet engines. Under high heat, UNS N06600 Plate forms a protective oxide layer that makes it heat-resistant. Additionally, these alloys are highly resistant to pressure, oxidation and corrosion.

Plates, sheets and strips of ASTM B168 UNS N06600 may be furnished in the following conditions & surface finishes:

Inconel 600 hot-rolled plate: annealed; or as-rolled.

Inconel 600 hot-rolled sheet: annealed.

Inconel 600 cold-rolled sheet: annealed; or hard.

Inconel 600 cold-rolled strip: annealed; skin-hard; quarter-hard; half-hard; or three-quarter-hard; hard; or spring.

Inconel 600 Sheet & Plates Equivalent Grades

STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Chemical Composition of Inconel Alloy 600 Sheet & Plate

Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015 max | 0.50 max | 6 – 10 | 72.00 min | 14 – 17 |

Mechanical Properties of Inconel 600 Sheet & Plates

Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

Characteristics

Resistant to a wide range of corrosive media. The chromium content gives better resistance than Alloy 200 and 201 under oxidizing conditions, at the same time the high nickel gives good resistance to reducing conditions.

Virtually immune to chlorine ion stress corrosion cracking.

Demonstrates adequate resistance to organic acids such as acetic, formic and stearic.

Excellent resistance to high purity water used in primary and secondary circuits of pressurized nuclear reactors.

Little or no attack occurs at room and elevated temperatures in dry gases, such as chlorine or hydrogen chloride. At temperatures up to 550C in these media, this alloy has been shown to be one of the most resistant of the common alloys.

At elevated temperatures the annealed and solution annealed alloy shows good resistance to scaling and has high strength.

The alloy also resists ammonia bearing atmospheres, as well as nitrogen and carburizing gases.

Under alternating oxidizing and reducing conditions the alloy may suffer from selective oxidation.

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone