- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

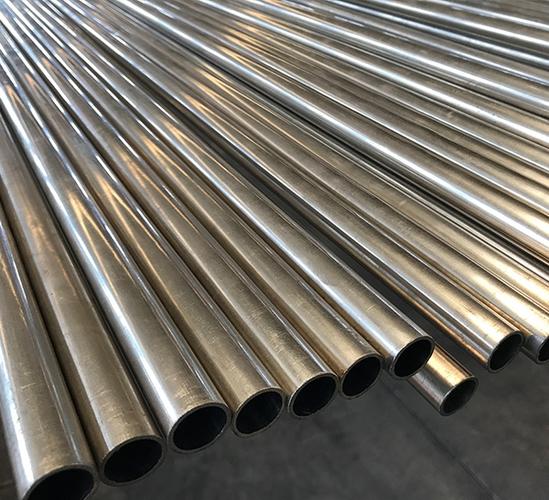

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

Nickel 200 201 Pipe Tube

-

Type: Seamless, Welded

OD: 1/2"-48"

Thickness: SCH5-SCHXXS

Length: 0-12M, Customized

Process: Hot/Cold Rolled,Hot work,Cold drawn

Nickel 200 201 pipe tube

Nickel 200 Pipe, Nickel 201 Pipe, Ni 200 seamless Pipe, Ni 201 seamless Pipe, Alloy 200 Pipe, Alloy 201 Pipe, UNS N02200 Tube, UNS N02201 Tube, Nickel Pipe Suppliers and Exporters, Nickel 201 Welded Pipe, Nickel 200 Welded Pipe, Nickel Alloy Pipe Manufacturer in HT PIPE.

Nickel

alloys are a class of metal alloys that offer excellent resistance to

corrosion and high-temperature applications. Nickel alloy pipes are

utilized in a variety of industries such as chemical, oil and gas,

aerospace, and others.

Nickel 200 and Nickel 201 pipe are both covered by various national and international standards such as ASTM B161, ASTM B163, ASTM B725, ASTM B730, and others. These standards ensure the quality of the pipes and their suitability for different applications.

The production of nickel alloy pipes involves various advanced processes such as extrusion, forging, and welding. The choice of manufacturing process depends on the desired application and properties of the final product.

Nickel Alloy 200, 201 Pipe Tube Specifications

Specifications: ASTM B 161 ASME SB 161 / ASTM B 622 ASME SB 622 / ASTM B725 ASME SB725, ASTM B 163 ASME SB 163

Dimensions: ASTM, ASME and API

Size: 15″NB TO 150″NB IN

Specialized in: Large Diameter Size

Type: Seamless / ERW / Welded / Fabricated

Form: Round, Hydraulic Etc

Length: Single Random, Double Random & Cut Length.

End: Plain End, Beveled End, Treaded

The difference bewteen Nickel 200 and Nickel 201 Chemical Composition

Nickel 200 is a commercially pure nickel alloy while Nickel 201 is an alloy with low carbon content. Nickel 200 contains around 99.6% of nickel and other elements like iron, copper, and manganese. In contrast, Nickel 201 contains approximately 99.2% nickel and 0.02% carbon. These alloys exhibit high melting points, excellent corrosion resistance, and good thermal and electrical conductivity.

Nickel Alloy 200, 201 Pipe Properties

Nickel 200 and 201 both exhibit exceptional resistance to virtually all alkalies, acids, and organic compounds. They also have higher thermal and electrical conductivity in comparison to other alloys. These alloys are very ductile and malleable, making them easy to work with. Additionally, these alloys possess high strength even at elevated temperatures.

| Condition and Size | Tensile Strength min psi(MPa) | Yield Strength (0.2 % offset) min psi(MPa) | Elongation in 2 in. or 50 mm (or4D), min, % | ||||

| Ni(UNS N02200) | Low-CarbonNi(UNS N02201) | Ni(UNS N02200) | Low-CarbonNi(UNS N02201) | Ni(UNS N02200) | Low-CarbonNi(UNS N02201) | ||

| Annealed | OD≤5in.(127mm) | 55000(380) | 50000(345) | 15000(105) | 12000(80) | 35 | 35 |

| OD>5in.(127mm) | 55000(380) | 50000(345) | 12000(80) | 10000(70) | 40 | 40 | |

| Stress-Relieved | All sizes | 65000(450) | 60000(415) | 40000(275) | 30000(205) | 15 | 15 |

Nickel alloy pipes Application

Nickel 200 and 201 are suitable for a variety of applications that require high corrosion resistance and high-temperature performance. These alloys are often used in chemical processing, oil and gas production, aerospace, and nuclear power generation. Their excellent properties make them suitable for manufacturing heat exchangers, valves, pumps, piping, and other critical components that operate under high-stress conditions.

In conclusion, Nickel 200 and Nickel 201 are two popular nickel alloy pipes with excellent properties and versatility. Their chemical composition, physical properties, and production processes make them suitable for various critical applications in demanding industries. Additionally, following proper guidelines and standards will ensure the quality of these alloys. It is imperative to consult with experts in the field to determine which alloy is suitable for your specific application.

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone