- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

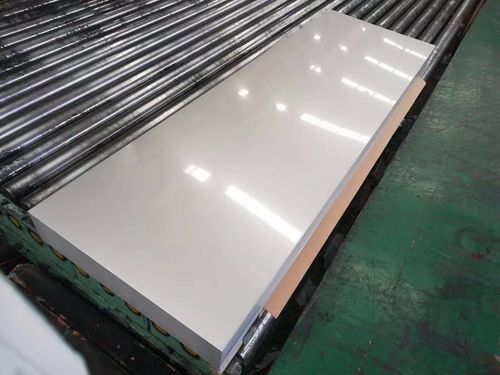

Hastelloy C276 Plate

-

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

Hastelloy N10276 Plate, 2.4819 Alloy C 276 Plate, Hastelloy Alloy C276 Sheet, ASTM B575 Hastelloy C276 Plate, Hastelloy C276 Plate

Alloy C-276 (UNS N10276, W.Nr. 2.4819) is known for its corrosion resistance in a wide range of aggressive media. The high molybdenum content of Hastelloy N10276 Plate imparts resistance to localized corrosion such as pitting. The low carbon minimizes carbide precipitation during welding to maintain resistance to intergranular attack in heat-affected zones of welded joints. Hastelloy C276 Plate is used in chemical processing, pollution control, pulp and paper production, industrial and municipal waste treatment and the recovery of “sour” natural gas.

ASTM B575 UNS N10276 Hastelloy C276 Sheet is frequently utilized in several industries, consisting of petrochemical, chemical oil and gas, power generation, pharmaceutical, pulp and paper manufacturing and drainage treatment. Hastelloy C276 Coil has superior resistance to matching, tension deterioration breaking as well as oxidizing environments. Hastelloy C276 Plate likewise displays resistance to deterioration by salt water in crevice conditions, which can generate hostile attack in other commonly utilized materials. Hastelloy Plate is usually remedy heat-treated at 2050 Degree F and fast quenched.

1.What are the Benefits?

Hastelloy C-276 Alloy has excellent resistance to a wide variety of chemical process environments, including:

Strong oxidizers (such as ferric and cupric chlorides)

Hot contaminated media (organic and inorganic)

Chlorine

Formic and acetic acids

Acetic anhydride

Seawater and brine solutions

Moreover, it's used in flue gas desulfurization systems because of its excellent resistance to sulfur compounds and chloride ions encountered in most scrubbers. The product, such as Hastelloy C-276 pipe, also has excellent resistance to pitting and to stress-corrosion cracking. It's one of the few materials that withstands the corrosive effects of wet chlorine gas, hypochlorite, and chlorine dioxide.

2.Specifications

Hastelloy alloy C-276 is designated as UNS N10276 and Werkstoff Nr. 2.4819. It is listed in NACE MR0175 for oil and gas service.

Rod, Bar, Wire and Forging Stock: ASTM B 462 (Rod, Bar and Forging

Stock), ASTM B 564 & ASME SB 564 (Forgings), ASTM B 574 & ASME

SB 574 (Rod, Bar and Wire), ISO 9723 (Rod and Bar), ISO 9724 (Wire), ISO

9725 (Forgings), DIN 17752, DIN 17753, DIN 17754, VdTÜV 400/12.98

Plate, Sheet and Strip: ASTM B 575; ASTM B 906; ASME SB 575; ASME SB 906, ISO 6208, DIN 17750, VdTÜV 400/12.98.

Pipe and Tube: - ASTM B 622; ASTM B 829 & ASME SB 622 ASME SB 829

(Seamless Tube), ASTM B 626; ASTM B 751 & ASME SB 626; ASME SB 751

(Welded Tube), ASTM B 619; ASTM B 775 & ASME SB 619; ASME SB 775

(Welded Pipe), ISO 6207 (Seamless Tube), DIN 17751, VdTÜV 400/12.98.

3.Chemical Composition

Limiting Chemical Composition, %

Nickel .............................................................................Balance

Molybdenum ...............................................................15.0-17.0

Chromium....................................................................14.5-16.5

Iron..................................................................................4.0-7.0

Tungsten ..........................................................................3.0-4.5

Cobalt ...........................................................................2.5 max.

Manganese ...................................................................1.0 max.

Carbon........................................................................0.01 max.

Vanadium....................................................................0.35 max.

Phosphorus ................................................................0.04 max.

Sulfur ..........................................................................0.03 max.

Silicon .........................................................................0.08 max

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone