- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

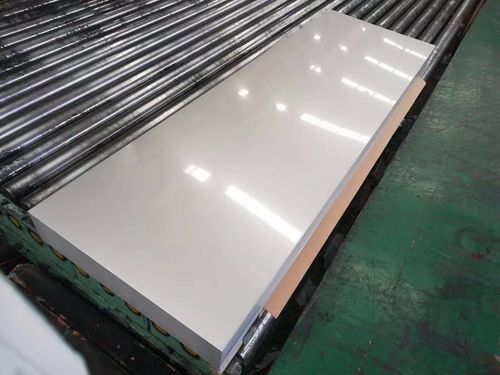

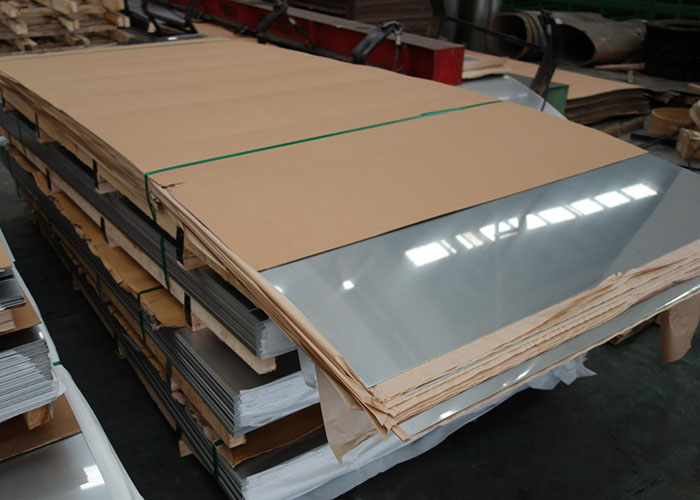

Duplex Steel S31254 Plate Sheet

-

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

Duplex steel UNS S31254 plate, also known as 6% Molybdenum, is a highly corrosion-resistant alloy that is ideal for use in severe environments. It is a type of austenitic-ferritic stainless steel that provides excellent resistance to chloride stress corrosion cracking and pitting corrosion. Below includes the standards, process, chemical composition, physical properties, and applications of Duplex steel UNS S31254 plate.

Duplex steel UNS S31254 plate complies with several standards such as

ASTM A240, ASTM A479, ASTM A182, ASME SA240, and ASME SA479. The

production process of UNS S31254 plate includes melting, hot rolling,

annealing, pickling, cold rolling, and cutting. The melting process is

done in an electric arc furnace or an induction furnace. The hot rolling

process involves heating the steel to a high temperature and then

rolling it into the desired thickness. Annealing is done to improve the

ductility and toughness of the steel. Pickling is a process that removes

any scale or oxide that may be on the surface of the steel. Cold

rolling is done to reduce the thickness of the steel to the desired

level. Finally, the plate is cut according to the required dimensions.

The chemical composition of Duplex steel UNS S31254 plate is as follows:

- Carbon: 0.020% maximum

- Manganese: 1.00% maximum

- Phosphorus: 0.030% maximum

- Sulfur: 0.010% maximum

- Silicon: 0.80% maximum

- Chromium: 20.00-22.00%

- Nickel: 17.50-18.50%

- Molybdenum: 6.00-6.50%

- Nitrogen: 0.18-0.22%

UNS S31254 stainless steel PHYSICAL PROPERTIES

| Melting Point | Density | Specific Gravity | Modulus of Elasticity |

| in Tension | |||

| 1320-1390 ℃ | 8.0 g/cm3 | 7.8 | 195 GPa |

254 SMO duplex steel plate MECHANICAL PROPERTIES

| Alloy | Tensile Strength Minimum(psi) | Yield Strength Minimum 0.2% offset (psi) | % Elongation in 2" Minimum |

| 254SMO | 98,600 | 43,500 | 50 |

Duplex steel UNS S31254 plate has a wide range of applications in many industries such as chemical processing, oil and gas, marine engineering, paper and pulp, and food processing. It is commonly used in equipment for handling corrosive fluids, heat exchangers, pressure vessels, and piping systems that carry hot and cold fluids. It is also used in the manufacture of pumps, valves, fittings, and flanges.

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone