- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

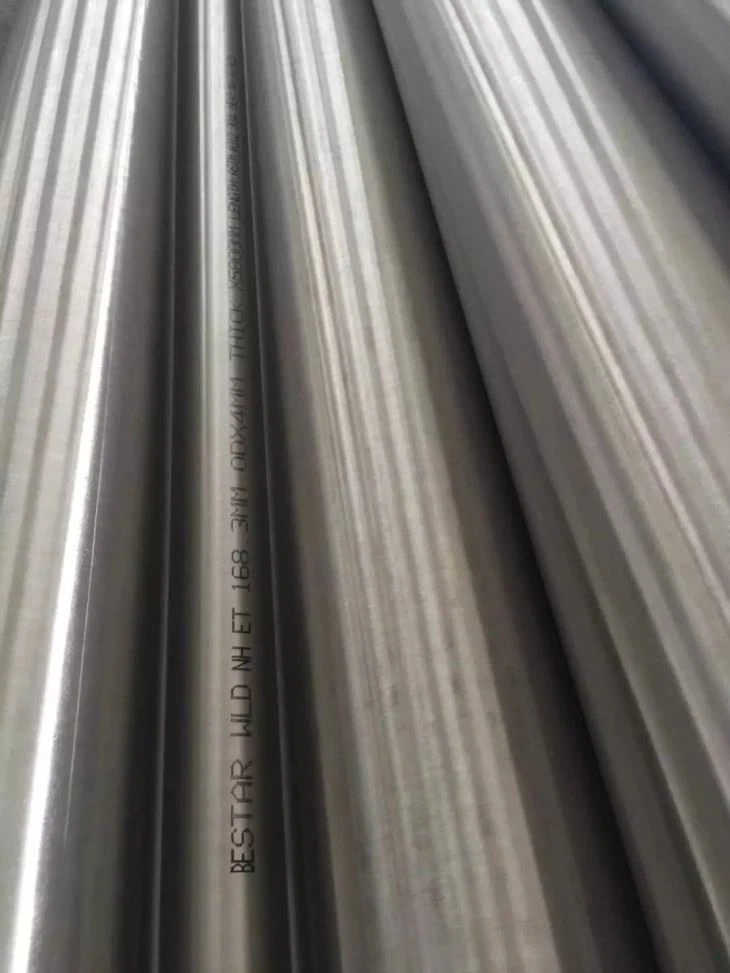

S31254 Pipe

-

Size:1/2"-48"

Length:Single Random, Double Random & Cut Length.

End :Plain End, Beveled End, Treaded

S31254 Pipe is a high-performance austenitic stainless steel pipe. It is also known as 6% Moly or Super Duplex Stainless Steel. The ASTM designation for this alloy is A312, and it is commonly used in corrosive environments such as chemical processing, pulp and paper, and petrochemical industries.

The standard process for manufacturing S31254 Pipe involves a series of steps. The first step is to melt the steel in an electric arc furnace. The steel is then refined using an argon-oxygen decarburization process. This process helps to remove impurities such as carbon and sulfur. The refined steel is then poured into casting molds where it solidifies into a billet. The billet is then hot rolled into a pipe.

SMO 254 Seamless Pipes Specifications

| Specifications | ASTM A 409 ASME SA 409 / ASTM A 312 ASME SA 312 / ASTM A 358 ASME SA 358 |

| Dimensions | ASTM, ASME and API |

| Size | 1/2″ – 48″ |

| Specialized in | Large Diameter Size |

| Thickness | 20 Swg., 18 Swg., 16 Swg., 14 Swg., 12 Swg., 10 Swg., & Sch. 10, Sch. 40, Sch. 80 etc. |

| Type | Seamless / ERW / Welded / Fabricated |

| Form | Round, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

SMO 254 Pipes Chemical Composition

| SMO 254 | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | – | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

SMO 254 Pipe Mechanical Properties

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

Equivalent Grades for 254 SMO Pipe

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | SIS | GOST |

| SMO 254 | S31254 | 1.4547 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 | – | 2378 | – |

254 SMO Pipes Test Certificates

• EN 10204/3.1B,

• Raw Materials Certificate

• 100% Radiography Test Report

• Third Party Inspection Report, etc

S31254 Pipe Application:

Due

to its excellent corrosion resistance and mechanical properties, S31254

Pipe is commonly used in applications where high levels of corrosion

resistance are required. It is used in chemical processing, pulp and

paper, and petrochemical industries. It is also used in offshore oil and

gas applications, such as subsea pipelines, where corrosion resistance

is essential. Other applications include heat exchangers, desalination

plants, and pharmaceutical industries.

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone