- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

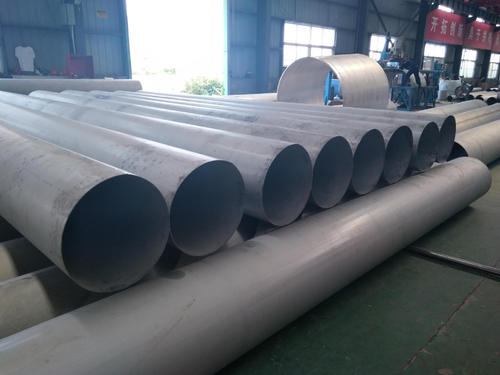

S32750 Pipe

-

ASTM A815 ASTM A312 A789 A790 UNS 32750 Welded pipe seamless pipe steel tube

OD: 1/2"-48"

Thickness: SCH5-SCHXXS

Length: 0-12M, Customized

Process: Hot/Cold Rolled,Hot work,Cold drawn

ASTM A815 ASTM A312 ASTM A789 ASTM A790 ASTM A928 UNS 32750 Welded pipe seamless pipe steel tube

Welded steel pipe (steel pipe manufactured with a weld) is a tubular product made out of flat plates, known as skelp, that are formed, bent and prepared for welding. Electric Resistance Welded Pipe. High Frequency Induction Welded Pipe. Spiral submerged-arc welding pipes.

HT PIPE is the ASTM A 790 UNS S32750 Duplex Steel werkst off nr. 1.4410 Pipes & Tubes Manufacturer, Exporter & Suppliers. Duplex 2507 Seamless Pipe, SAF 2507 Pipes, ASTM SA789 Duplex steel tubes, Duplex Steel 2507 Pipes, S32750 Duplex Steel Seamless Pipe, super duplex 1.4410 Tube, 2507 welded pipe Manufacturer in China.

Super duplex 1.4410 Material Specfication and Dimension Standards:

| Product Category | Material Specification as per ASME/ASTM | Dimension Standards |

|---|---|---|

| Seamless Pipes | Welded Pipes | ASTM A815, ASTM A312, ASTM A789, ASTM A790, ASTM A928, ASTM A240 | ANSI B36.10, ANSI B36.19 |

Super duplex 2507 Pipe Size Range:

| 1/4" to 16" | Sch 5, Sch 5s, Sch 10, Sch 10s, Sch 20, Sch 30, Sch 40s, Sch 40, Sch STD, Sch 60, Sch 80s, Sch 100, Sch 120, Sch XS, Sch XXS, Sch 160 |

The difference between Super duplex UNS S32750 and S32760:

| Trade Name | UNS | Super Duplex Industry Specifications | Chemical Composition | Min.Tensile (KSI) | Min.Yield (KSI) | Elongation % |

|---|---|---|---|---|---|---|

| SAF 2507® | UNS S32750 | ASTM A182 F53, A240, A276, A479, A789, A790, A815, A928, A988 SAE J405 | C 0.030 max Cr 24.0-26.0 Cu 0.5 max Mn 1.20 max Mo 3.0-5.0 N 0.24-0.32 Ni 6.0-8.0 P 0.035 max S 0.020 max Si 0.8 max | 116 | 80 | 15 |

| UNS S32760 | ASTM A182 F55, A240, A276, A314, A473, A479, A789, A790, A815, A928, A988 SAE J405 | C 0.03 max Cr 24.0-26.0 Cu 0.5-1.0 Mn 1.0 max Mo 3.0-4.0 N 0.2-0.3 Ni 6.0-8.0 P 0.03 max S 0.01 max Si 1.0 max W 0.5-1.0 | 109 | 80 | 25 |

Duplex 2507 Overview

Duplex 2507 is a super duplex stainless steel designed for applications which demand exceptional strength and corrosion resistance. Alloy 2507 pipe has 25% chromium, 4% molybdenum, and 7% nickel. This high molybdenum, chromium and nitrogen content results in excellent resistance to chloride pitting and crevice corrosion attack and the duplex structure provides 2507 with exceptional resistance to chloride stress corrosion cracking.

Usage of Duplex 2507 should be limited to applications below 600° F (316° C). Extended elevated temperature exposure can reduce both the toughness and corrosion resistance of alloy 2507.

Duplex 2507 possesses excellent mechanical properties. Often a light gauge of 2507 material can be used to achieve the same design strength of a thicker nickel alloy. The resulting savings in weight can dramatically reduce the overall cost of fabrication.

Corrosion Resistance

2507 Duplex is highly resistant to uniform corrosion by organic acids such as formic and acetic acid. It is also highly resistant to inorganic acids, especially if they contain chlorides. Alloy 2507 is highly resistant to carbide-related intergranular corrosion. Due to the ferritic portion of the duplex structure of the alloy it is very resistant to stress corrosion cracking in warm chloride containing environments. Through additions of chromium, molybdenum and nitrogen localized corrosion such as pitting and crevice attack are improved. Alloy 2507 has excellent localized pitting resistance.

What are the characteristics of Duplex 2507?

High resistance to chloride stress corrosion cracking

High Strength

Superior resistance to chloride pitting and crevice corrosion

Good general corrosion resistance

Suggested for applications up to 600° F

Low rate of thermal expansion

Combination of properties given by austenitic and ferritic structure

Good weldability and workability

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone