- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

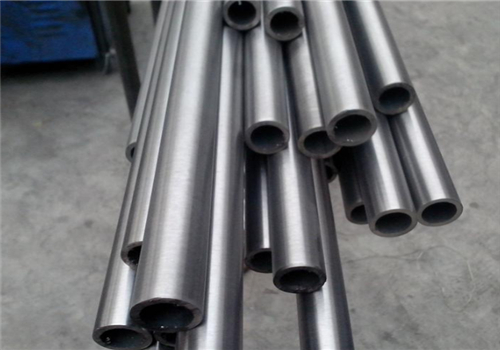

Hastelloy Tube

-

Material: ASTM B622, Hastelloy B2,B3,C22,C2000,C276,X

Size: 1/4"-3", 0.54mm-88.9mm

WT: SCH10,SCH40,SCH80

Type: Hastelloy seamless tube

HT PIPE as the reliable Hastelloy tube suppliers, Hastelloy Seamless Tubes, Hastelloy tube manufacturers in China, provide Hastelloy B2 tube, Hastelloy B3 tube, Hastelloy C2000 tube, Hastelloy C22 tube, Hastelloy X tube, Hastelloy C276 tube.

Hastelloy tube is a highly durable and corrosion-resistant nickel-chromium-molybdenum alloy. The ASTM B622 specification governs the requirements, dimensions, finish, testing, and packaging of seamless nickel and nickel alloy tubes.

The common grades used in tube production include Hastelloy B-2, B-3, C22, C276, C200 and X. These grades differ in terms of their chemical composition and properties, such as Hastelloy B-2 is a nickel-molybdenum alloy that boasts superior resistance to reducing agents such as hydrochloric acid, sulfuric acid, and phosphoric acid. It is highly resistant to stress corrosion cracking and pitting in chloride solutions, making it a popular choice for chemical processing equipment; While Hastelloy C-276 is a versatile nickel-chromium-molybdenum-tungsten alloy that offers excellent resistance to oxidizing and reducing environments. It is highly resistant to corrosion by sulfuric acid, hydrochloric acid, and chlorine gas. It is also resistant to crevice corrosion, intergranular corrosion, and pitting.

ASTM B622 Hastelloy Tube Specification:

Grades: B2, B3, C22, C2000, C276, X

Size: 1/4"-3", 0.54mm-88.9mm

Wall thickness: SCH10,SCH40,SCH80

Hastelloy Tube End: Plain End, Beveled End, Treaded Tube

Application & uses of Hastelloy Tube: Oil Tube, Gas Tube, Fluid Tube, Boiler Tube, Heat exchanger Tube

All Hastelloy tube offers with EN10204, 3.1. The material test report (MTR) will be provided with the Hastelloy tubing.

ASTM B622 Hastelloy Tube Chemical Composition:

| Grade | UNS | C≤ | Mn≤ | P≤ | S≤ | Si≤ | Ni | Cr | Mo | Fe | Co≤ |

| B2 | N10665 | 0.02 | 1.0 | 0.04 | 0.03 | 0.10 | - | 1.0max | 26.0-30.0 | 2.0max | 1.0 |

| B3 | N10675 | 0.01 | 3.0 | 0.03 | 0.01 | 0.10 | 65.0min | 1.0-3.0 | 27.0-32.0 | 1.0-3.0 | 3.0 |

| X | N06002 | 0.05-0.15 | 1.0 | 0.04 | 0.03 | 1.0 | - | 20.5-23.0 | 8.0-10.0 | 17.0-20.0 | 0.5-2.5 |

| C22 | N06022 | 0.015 | 0.5 | 0.02 | 0.02 | 0.08 | - | 20.0-22.5 | 12.5-14.5 | 3.0-6.0 | 2.5 |

| C2000 | N06200 | 0.01 | 0.5 | 0.025 | 0.01 | 0.08 | - | 22.0-24.0 | 15.0-17.0 | 3.0max | 2.0 |

| C276 | N10276 | 0.01 | 1.0 | 0.04 | 0.03 | 0.08 | - | 14.5-16.5 | 15.0-17.0 | 4.0-7.0 | 2.5 |

ASTM B622 Hastelloy Tube Melting Point, Density And Tensile Strength

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| C22 | 8.69 G/Cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

| C276 | 8.89 G/Cm33 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40% |

| B2 | 9.2 G/Cm3 | 1370 °C (2550 °F) | Psi – 1,15,000 , MPa –760 | Psi – 52,000 , MPa – 350 | 40% |

| B3 | 9.2 G/Cm3 | 1370 °C (2550 °F) | Psi – 1,15,000 , MPa –760 | Psi – 52,000 , MPa – 350 | 40% |

| C2000 | 8.69 G/Cm³ | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45% |

| X | 8.22 G/Cm³ | 1355°C | 655 MPa | 240 MPa | 35% |

ASTM B622 Hastelloy Tube Schedules

| DN | NPS(in) | OD(mm) | Sch10 in(mm) | Sch40 in(mm) | Sch80 in(mm) |

| 8 | 1/4 | 13.72 | 0.065(1.65) | 0.088(2.24) | ... |

| 10 | 3/8 | 17.14 | 0.065(1.65) | 0.091(2.31) | 0.126(3.20) |

| 15 | 1/2 | 21.34 | 0.083(2.11) | 0.109(2.77) | 0.147(3.73) |

| 20 | 3/4 | 26.67 | 0.083(2.11) | 0.113(2.87) | 0.154(3.91) |

| 25 | 1 | 33.40 | 0.109(2.77) | 0.133(3.38) | 0.179(4.55) |

| 32 | 1 1/4 | 42.16 | 0.109(2.77) | 0.140(3.56) | 0.191(4.85) |

| 40 | 1 1/2 | 48.26 | 0.109(2.77) | 0.145(3.68) | 0.200(5.08) |

| 50 | 2 | 60.32 | 0.109(2.77) | 0.154(3.91) | 0.218(5.54) |

| 65 | 2 1/2 | 73.02 | 0.120(3.05) | 0.203(5.16) | 0.276(7.01) |

| 80 | 3 | 88.90 | 0.120(3.05) | 0.216(5.49) | 0.300(7.62) |

The ASTM B622 Hastelloy tube is commonly used in heat exchangers, condensers, reactors, evaporators, and other process equipment that require high strength, high corrosion resistance, and high heat resistance. It can also be used in marine, petrochemical, and power generation industries. It requires minimal maintenance and can last for decades without the need for replacements.

ASTM B622 Hastelloy tube is a highly reliable and durable choice for chemical processing equipment. Its excellent resistance to corrosion, stress corrosion cracking, and pitting makes it ideal for harsh environments. Its ability to withstand extreme temperatures and pressures makes it a popular choice for high-temperature and high-pressure applications in industries such as oil and gas, chemical, and power generation. Its long-lasting durability and minimal maintenance requirements make it a cost-effective solution for companies that rely on high-performance equipment.

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone