- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

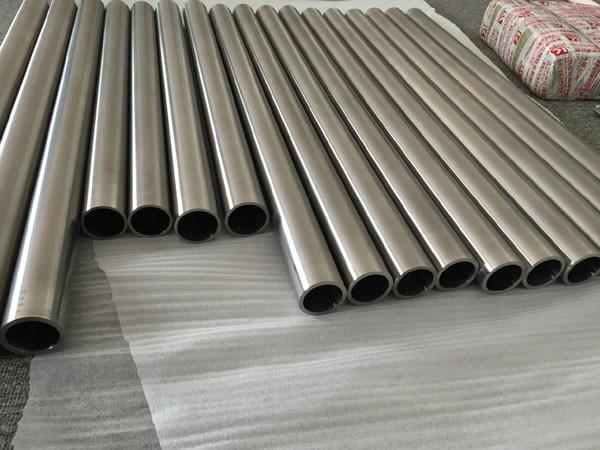

Nickel Steel Monel 400 Welded Pipe

-

Type: Seamless, Welded

OD: 1/2"-48"

Thickness: SCH5-SCHXXS

Length: 0-12M, Customized

Process: Hot/Cold Rolled,Hot work,Cold drawn

ASTM B474 Monel 400 welded pipe, UNS N04400 welded pipe, ASTM B474 UNS N04400 pipe, Alloy 400 welded pipe, NICKEL ALLOY UNS N04400 pipe, alloy 400 pipe, 2.4360 pipe, Monel 400 welded pipe manufacturer and supplier in China HT PIPE.

Monel 400 is a nickel-copper alloy that is extremely corrosion-resistant and has good mechanical properties at both room and elevated temperatures. Monel 400 welded pipe is made from this alloy, with welding being the primary method of fabrication according to ASTM B474, the Standard Specifification for Electric Fusion Welded Nickel and Nickel Alloy Pipe.

The specification of UNS N04400 Monel 400 welded pipe

| Material Grade | Nickel Alloy 400 Monel400 N04400 NS111 2.4360 welded pipe | ||||

| welding procedure | EFW/ ERW /SSAW /ARC | ||||

| Size | 1/2''~48'' | ||||

| Thickness | SCH5~SCHXXS | ||||

| End | Beveled End,Plain End | ||||

| Length | As per your requirement. | ||||

| Packing | Export Standard packing or as per your requirements. | ||||

Monel 400 welded pipe is typically produced using the TIG (Tungsten Inert Gas) welding process. This welding process involves a tungsten electrode and a shielding gas, which protects the weld pool and prevents oxidation. This process is preferred for Monel 400 because it produces a high-quality weld with low levels of oxidation and contamination.

The primary standard for Monel 400 welded pipe is ASTM B725. This standard covers welded pipe made from Monel 400, along with other nickel alloys. Other relevant standards include ASTM B165, ASTM B163, and ASTM B829.

Alloy 400 welded pipe Recommended Heat Treatment

| UNS Designation | Alloy | PWHT Deg ℉(Deg ℃) | Quench |

| N04400 | 400(Ni-Cu) | 1650-1700℉(900-928℃) | Rapid Air/water |

ASTM B474 Monel 400 welded pipe has excellent resistance to corrosion, particularly in seawater and other corrosive environments. It is also resistant to stress corrosion cracking, pitting, and crevice corrosion. The alloy has good mechanical properties at both room and elevated temperatures, which makes it well-suited for a wide range of applications. In addition, Monel 400 has good thermal conductivity and is non-magnetic.

In conclusion, Alloy 400 welded pipe is a highly corrosion-resistant alloy that is well-suited for a range of applications. Its excellent mechanical properties at both room and elevated temperatures, along with its resistance to stress corrosion cracking and other forms of corrosion, make it a popular choice for many industries. With its high resistance to corrosion and other destructive effects, Monel 400 welded pipe is a reliable and cost-effective option for many different applications.

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone