- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: +86 18865211873

WhatsApp: +86 18865211873

E-mail: ganmaimai@qq.com

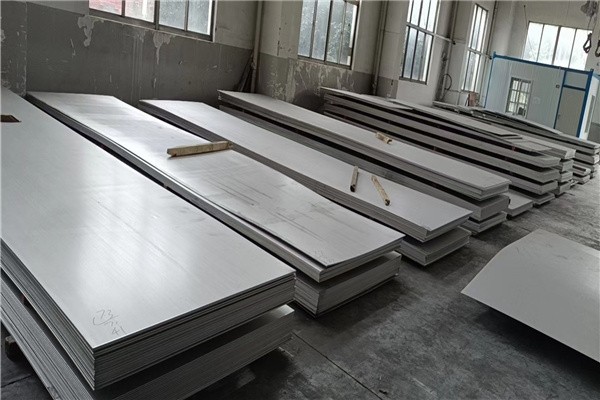

Duplex Steel S30815 Plate Sheet

-

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

UNS S30815 stainless steel plate supplier, UNS S30815 plate, 253MA steel plate, 1.4835 Duplex steel sheet, Duplex steel S30815 sheet, Duplex steel 1.4835 sheet, 253MA Duplex steel plate and sheet manufacturer in HT PIPE.

Stainless steel 253MA has high carbon content so is highly susceptible to sensitisation from service exposure or welding. Although not designed for aqueous corrosion resistance, the high chromium and nitrogen contents give it a pitting resistance approximating that of 316. Solution Treatment (Annealing) - Heat to 1050-1150°C and cool rapidly. To achieve maximum creep strength in service it is recommended that the material be solution treated after 10-20% cold work. It cannot be hardened by thermal treatment. It provides excellent weldability, 253MA welding with Grade 22.12HT rods or electrodes is pre-qualified by 1554.6. If lower creep strength can be tolerated Grade 309 fillers can be used.

Duplex Steel 1.4835 S30815 Plate Sheet Specification::

Standard: ASTM A240 / ASME SA240

Thickness: 1.0mm – 100mm

Width: 1000mm-2000mm

Production: Hot-Rolled (HR) / Cold-Rolled (CR)

Surface Finish: 2B, 2D, No.4, No.5, SB, HR, No.8, Mirror

Packaging: Loose / Carrate / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps

253MA UNS S30815 Plate Chemical Properties:

| % | Cr | Ni | Si | C | Mn | P | S | N | Ce | Fe |

| Min | 20 | 10 | 1.4 | 0.05 | - | - | - | 0.14 | 0.03 | Balance |

| Max | 22 | 12 | 2 | 0.1 | 0.8 | 0.04 | 0.03 | 0.2 | 0.08 | - |

UNS S30815 stainless steel plate Mechanical Properies:

| Tensile Str (MPa) min | Yield Str 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | |||

| 600 | 310 | 40 | 95 | 217 |

Heat Treatment

Solution Treatment (Annealing)

Heat to 1050-1150°C and cool rapidly. It is recommended that the material be solution treated after 10-20% cold work to achieve maximum creep strength in service. This grade cannot be hardened by thermal treatment.

Possible Alternative Grades

| Grade | Why it might be chosen instead of 253MA (UNS S30815) |

| 310 | Carburising atmospheres require a higher nickel content. |

| 304H | Lower cost alternative, with lower creep strength, for use up to about 800°C. |

| 321H | Lower cost alternative, with lower creep strength, for use up to about 800°C. |

| Nickel Alloys | Carburising atmospheres or temperatures above the 1100 - 1150°C maximum of S30815. |

The duplex UNS S30815 stainless steel plate is commonly used in various applications that require high strength, corrosion resistance, and good weldability:

1. Chemical processing industries: The duplex UNS S30815 stainless steel plate is widely used in chemical processing industries, especially in the production of hydrochloric and sulfuric acids. The alloy's high resistance to corrosion and stress cracking makes it an ideal choice for storage tanks, piping, and reactors.

2. Oil and gas industries: Duplex UNS S30815 stainless steel plates find extensive use in the oil and gas industries, where they are used for production tubing, piping, and other equipment. The alloy's high strength, corrosion resistance, and good weldability make it suitable for use in harsh environments.

3. Food processing industries: The duplex UNS S30815 stainless steel plate is widely used in the food processing industry, where it is used for production of different equipment such as knives, cutting boards, and food processing machinery.

4. Aerospace industries: The alloy's high strength-to-weight ratio and excellent corrosion resistance make it a preferred choice for aerospace applications such as airplane frames, missile components, and spacecraft structures.

5. Medical equipment: Medical equipment and devices such as surgical tools, implants, and surgical trays also use duplex UNS S30815 stainless steel plates. Its biocompatibility and resistance to corrosion and wear make it an ideal choice for such applications.

6. Construction industry: Duplex UNS S30815 stainless steel plates find use in construction applications such as building facades, roofing, and cladding due to their excellent corrosion resistance and durability.

Send Inquiry

Copyright © 2025-2026 Shandong Jute Steel Pipe Co.,Ltd. All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone